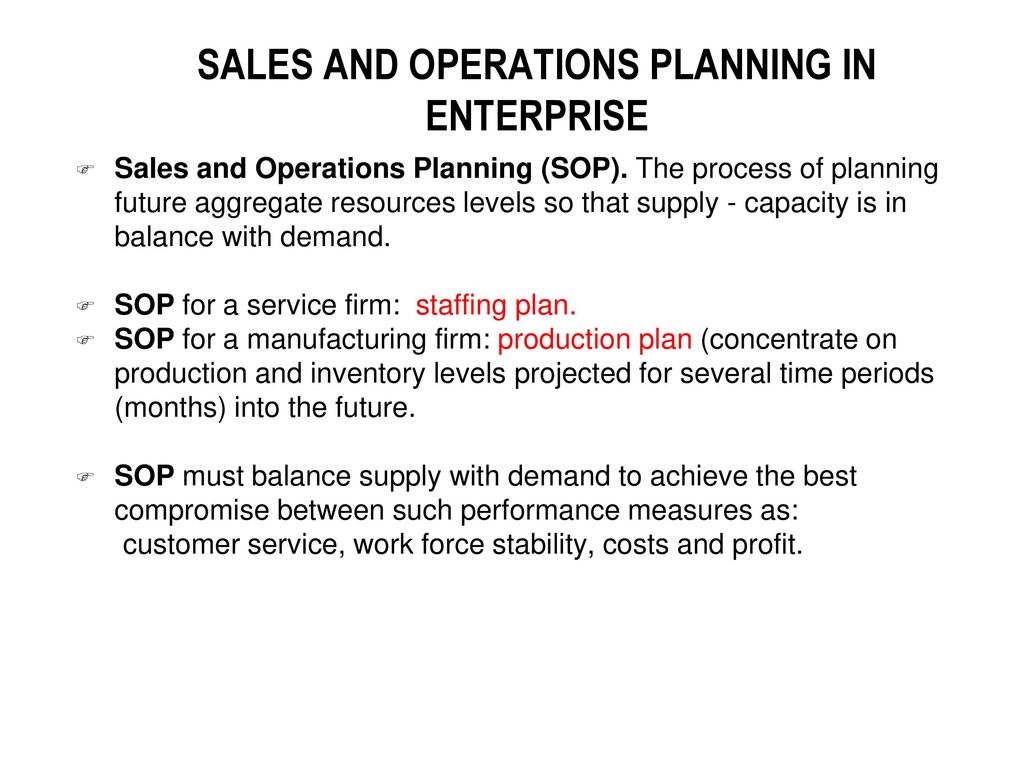

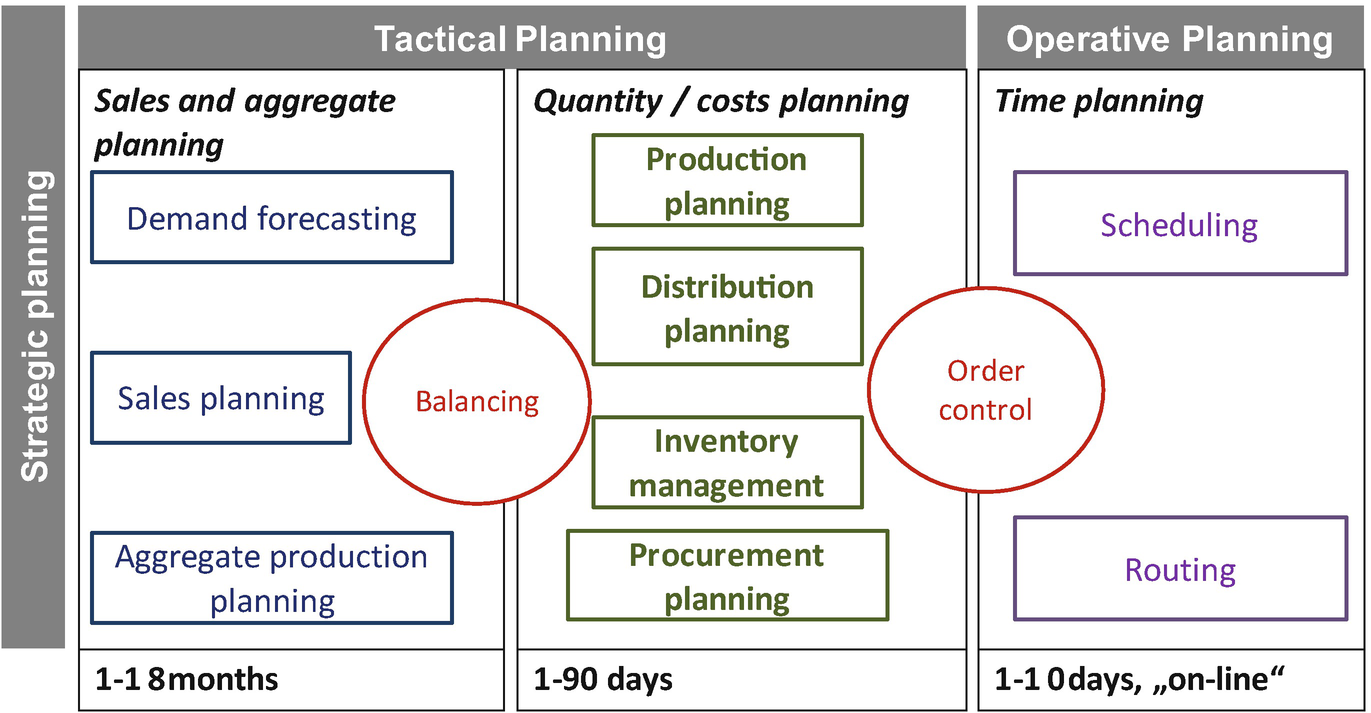

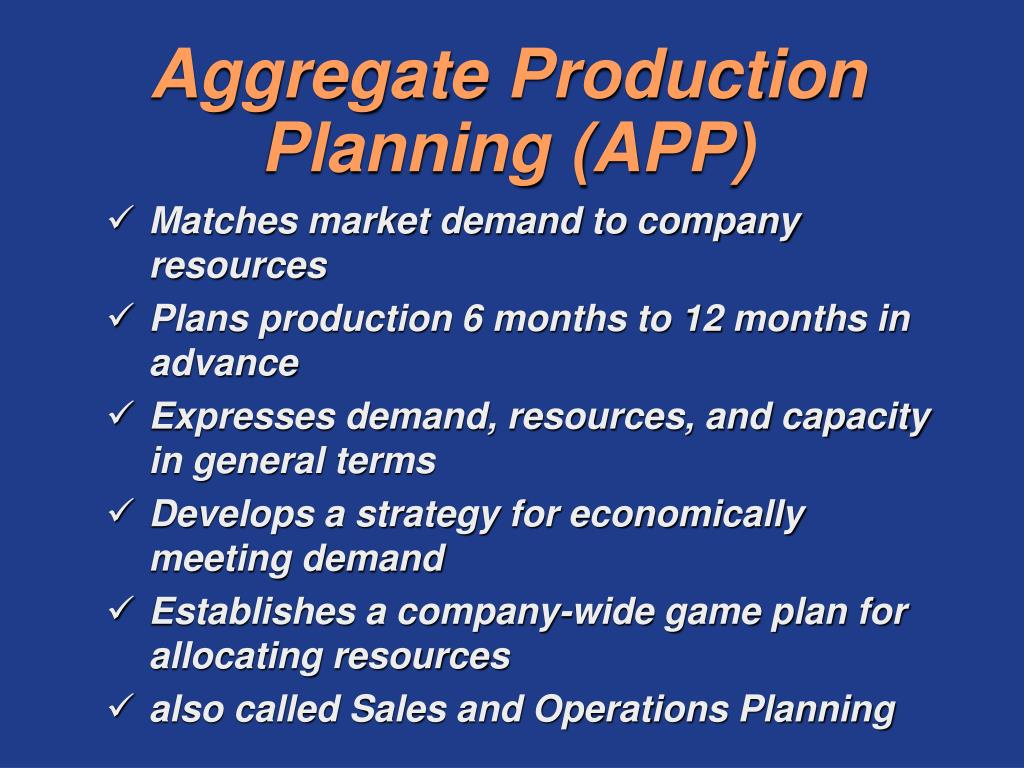

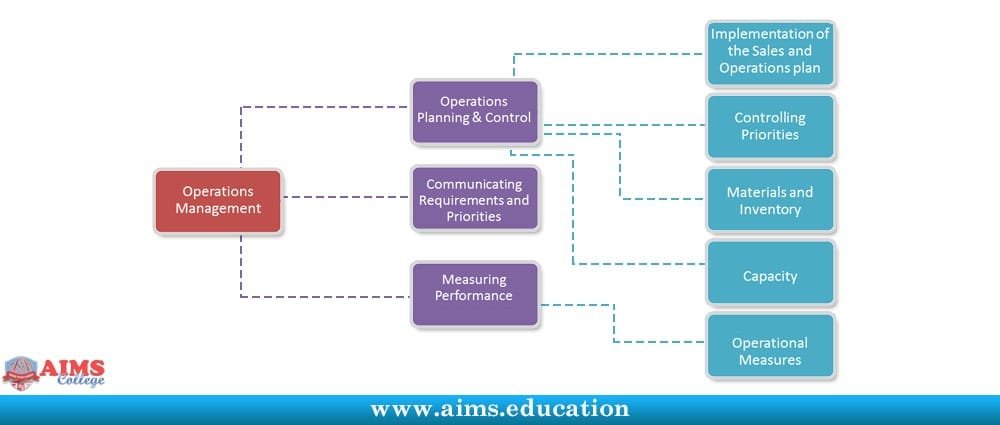

A) S&OP is also called an aggregate plan B) S&OP is used to determine which plans are feasible in the coming months and which areAggregate Planning Sales and operations planning (S&OP) A process of balancing resources and forecasted demand, while linking strategic planning with operations over all planning horizons S&OP receives input from a variety of sources both internal and external to the firm Because of the diverse inputs, S&OP is typically done by crossfunctional teams that align the competingFor our topic, we'll be specifically defining construction aggregate, or simply "aggregate", which you'll mostly hear in the groundworks and construction industry You can check with your local aggregate suppliers about the types of aggregate they offer, but knowing what exactly you need is important Let's explore the different types of aggregate and their uses The Different Types

Pdf Sales And Operations Planning S Op Concepts And Models Under Constraints Literature Review

S&op planning is also called aggregate planning. what is 'aggregate' about it

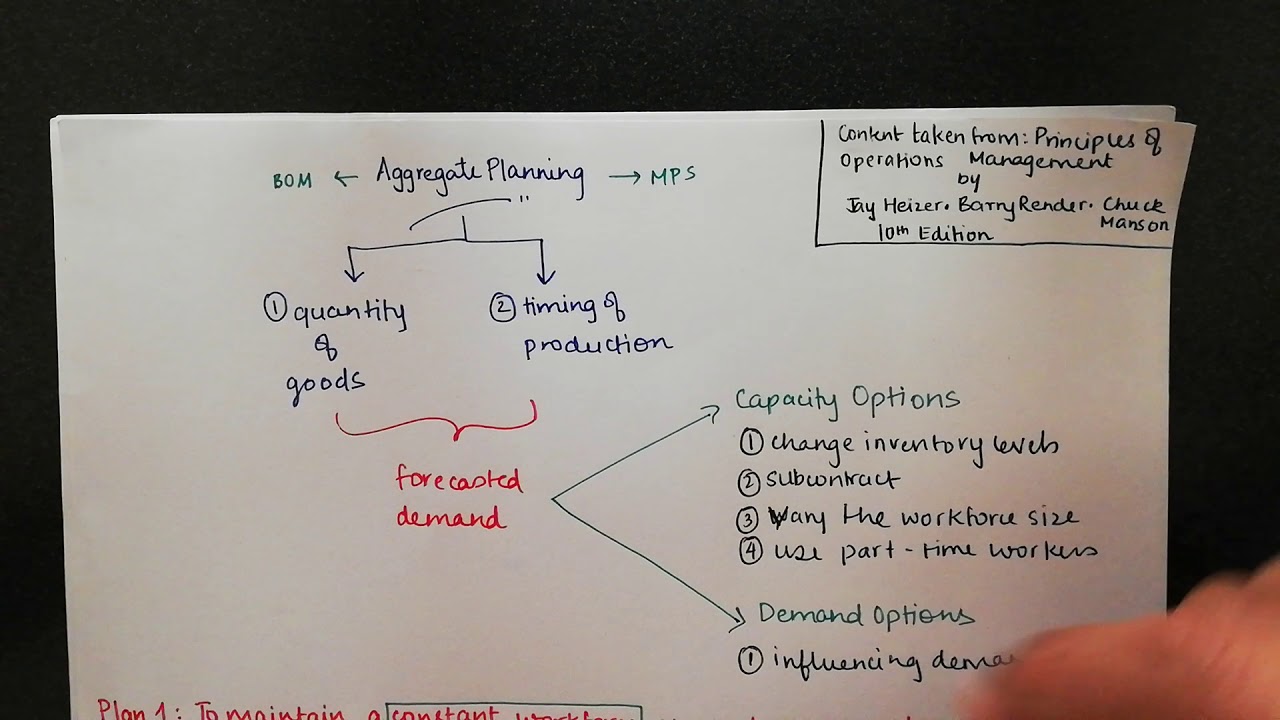

S&op planning is also called aggregate planning. what is 'aggregate' about it- · If a planning application is called in, the decision on whether or not to grant planning permission will be taken by the Secretary of State, usually afterAggregate planning is concerned with determining the quantity and timing of production in the intermediate term Which of the following statements is NOT true about S&OP?

Climbing The Sales Operations Maturity Ladder Stage 3 Consumer Goods Technology

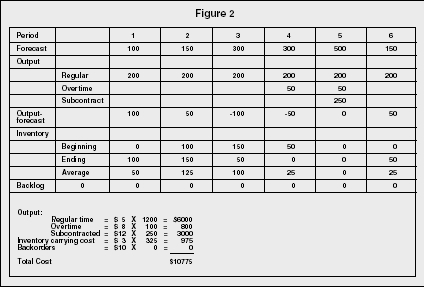

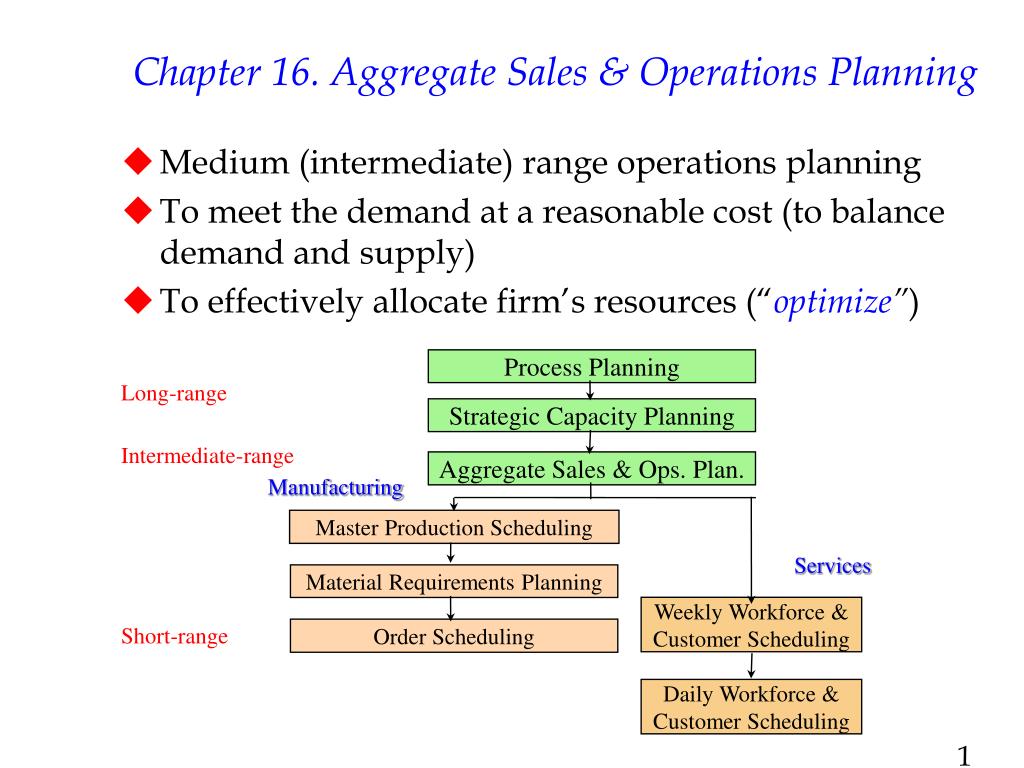

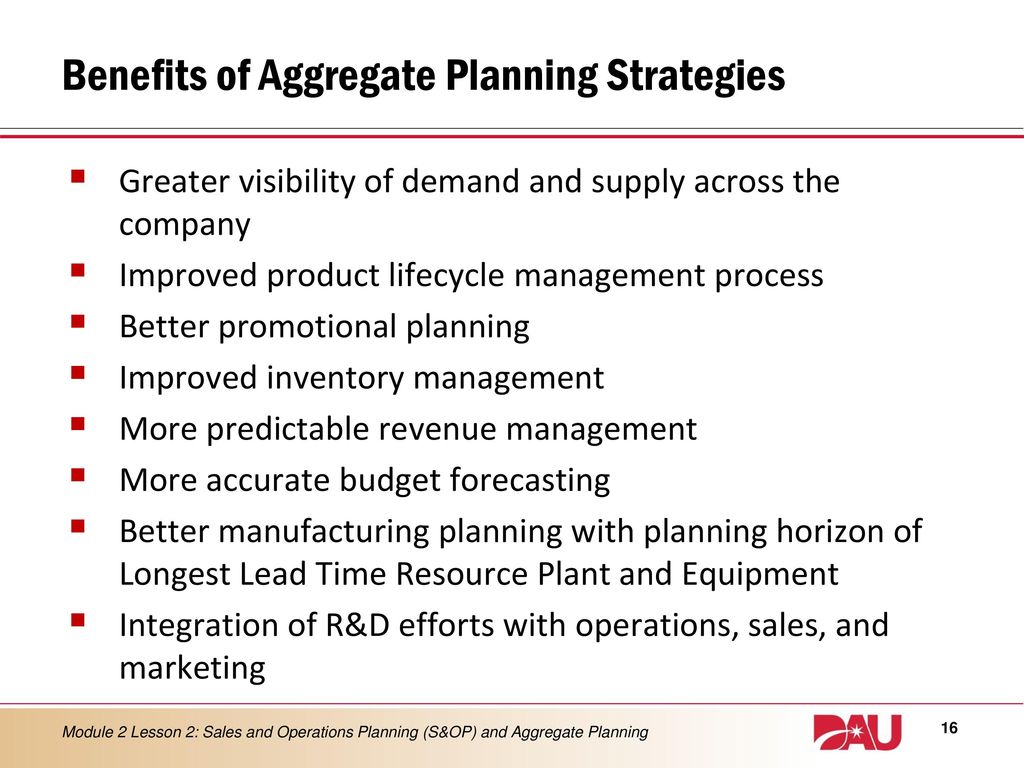

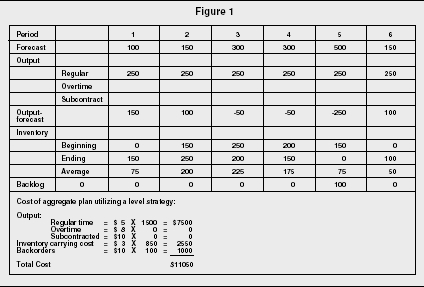

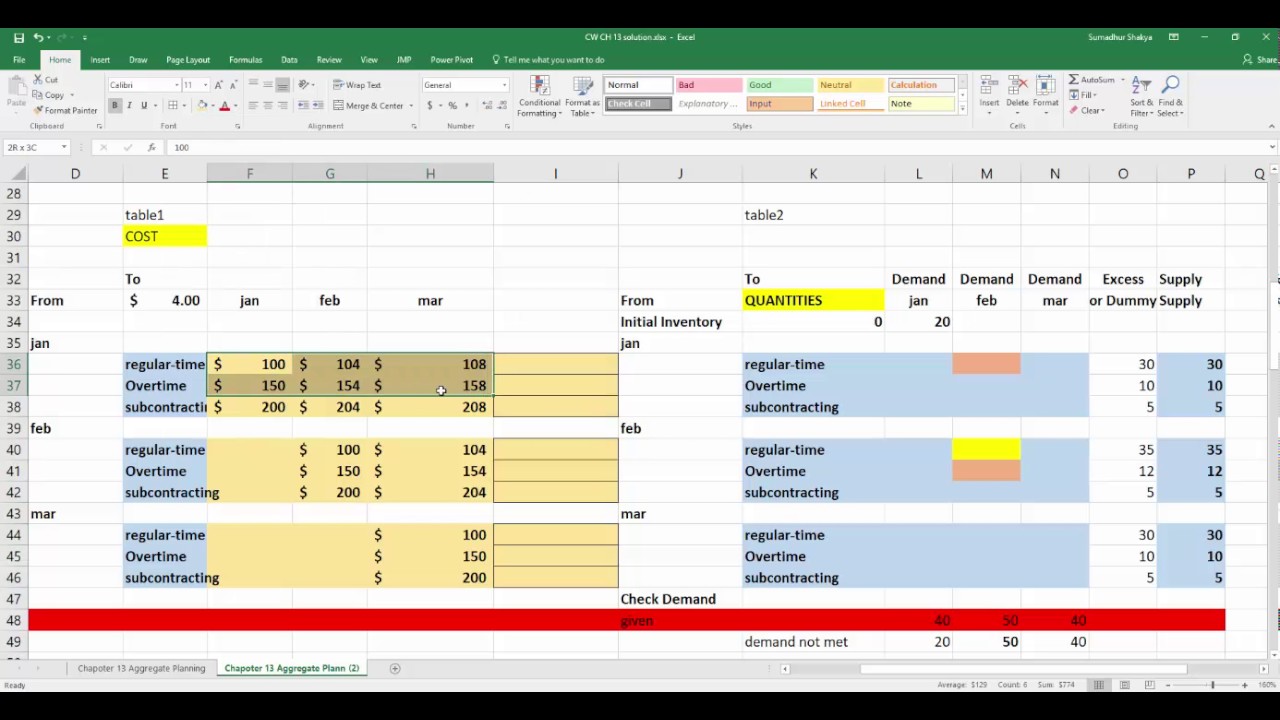

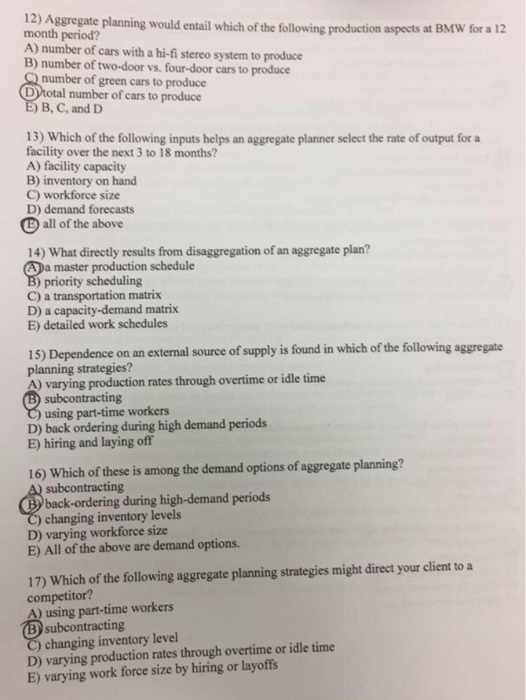

Aggregate production planning also exploits plant and equipment utilization and profits The efficiency of aggregate production planning is a production plan that indicates how many workers are needed in each period, the amount and type of production (such as regular, overtime, subcontracting, etc), and the units to be produced, stored, and back ordered per month or per quarter AggregateS&OP is used to determine which plans are feasible in the coming months and which are not B S&OP is typically done by crossfunctional teams that align competing constraints C When the resources appear to be substantially at odds with market expectations, S&OP provides advanced warning to top management D S&OP is also called an aggregate planAggregate planning is also called aggregate production planning or simply production planning The goal of Aggregate planning is to determine the aggregate levels of production, inventory, and workforce to respond to fluctuating demand in the next 6–18 months The term "aggregate" refers to some measure of output or input that permits aggregation across several products Thus, the

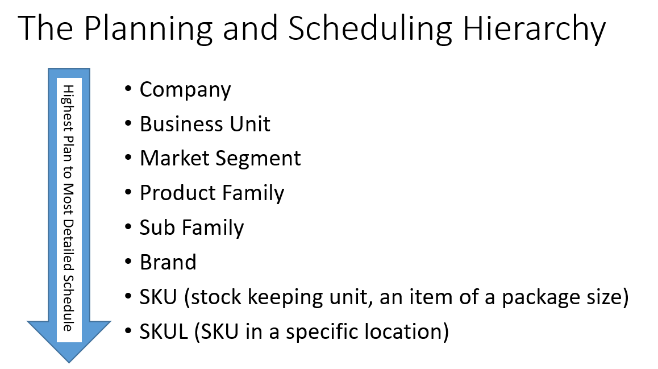

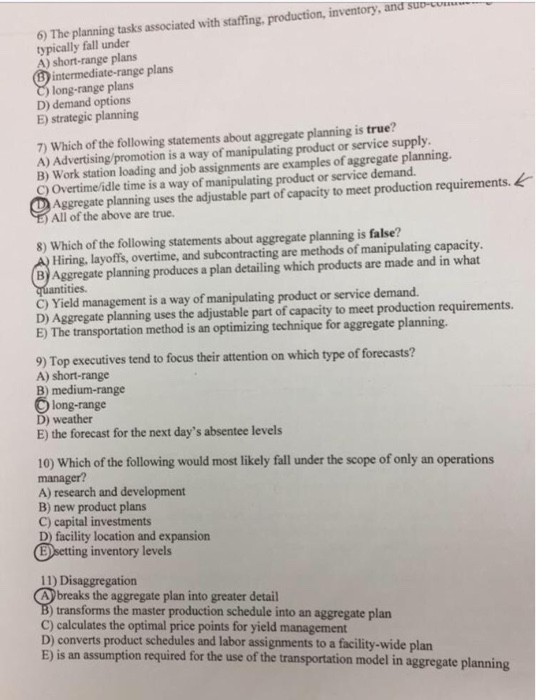

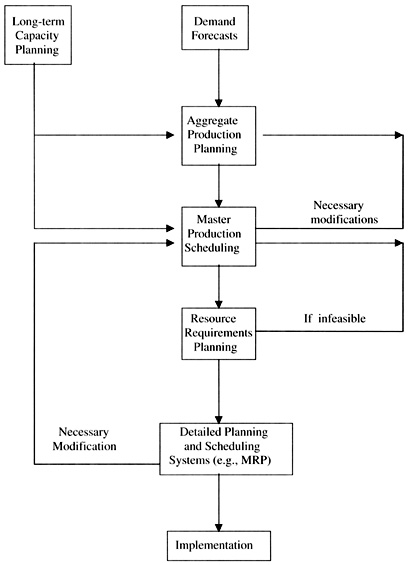

Aggregate planning is concerned with determining the quantity and timing of production in the A) short term B) long term C) next term D) intermediate term D) intermediate term Which of the following statements is NOT true about S&OP?Aggregate planning A is also called production planning B is concerned with meeting demand for the intermediate period at minimum cost C considers overtime, subcontracting, and inventory levels D All of the above E Only A and C above 6 In quality improvement, the fishbone chart A is used to identify potential causes for specific problems B shows the prevalence of the various81 Aggregate Planning Aggregate planning, also known as aggregate scheduling is concerned with determining the quantity and timing of production for the immediate future, often from three to eighteen months ahead Operations managers try to determine the best way to meet forecasted demand by adjusting production rates, labor levels, inventory levels, overtime work,

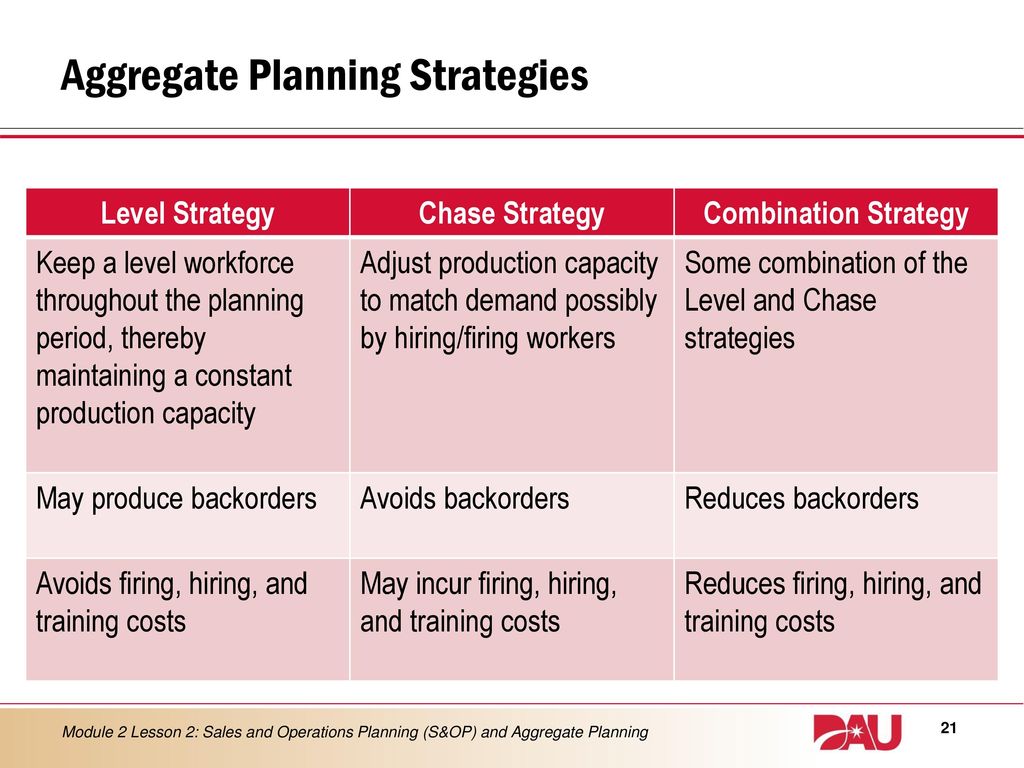

Role of Aggregate Planning in a Supply Chain Basic Assumptions A poor aggregate plan can result in lost sales, lost profits, excess inventory, or excess capacity 86 Aggregate Planning Strategies There is typically a tradeoff between optimizing for capacity (machinelabor), inventory, and backlog/lost sales – Chase strategy sync production with demand, hiring and firing as · Aggregate planning is also sometimes known as sales and operations planning Sales and operations planning is the intermediaterange decisions to balance supply and demand, integrating financial and operations planning It is hard for organizations to predict the exact quantity and timing of demands for specific products and services in advanceDisaggregation industries traditionally associate with revenue management operate in which quadrant of the Revenue Management Matrix?

Chapter 19 Sales And Operations Planning Studocu

Production Planning Control Chapter 2 Aggregate Planning Master Production Scheduling Chapter2 1 Pdf Free Download

· Aggregate Planning and Production Planning The production plan is essentially the output of aggregate planning Using the concept of aggregation to translate demand into production rates plan include consideration of demand requirements by setting output, employment, and finishedgoods inventory levels or service capacities In aggregate, PlannerEg, passenger tires • in aggregate terms such as total units (eg Camry s), standard labor hours or dollarsAggregate planning is concerned with determining the quantity and timing of production in the intermediate term Which of the following statements is NOT true about S&OP?

Aggregate Planning And S Op Sales And Operations Planning 533 The Nature Of Aggregate Planning 534 Aggregate Pdf Document

Tactical Sales And Operations Planning A Holistic Framework And A Literature Review Of Decision Making Models Sciencedirect

1 Aggregate Production Planning Aggregate production planning is concerned with the determination of production, inventory, and work force levels to meet °uctuating demand requirements over a planning horizon that ranges from six months to one year Typically the planning horizon incorporate the next seasonal peak in demand The planning horizon is often · Aggregate planning is essentially a major picture approach to planning Planners for the most part attempt to avoid focusing on singular products or services except if, obviously, the organization has just one major product or service Instead, they centeraround overall, or aggregate, capacity Aggregate planning is firmly related to other corporate decisionsAggregate planning serves as the basic structure for the future short – range type planning and this type of planning can be categorized as follows – 1Productionplan– • Also called as the manufacturing aggregate plan • Is a managerial statement of the period – by – period production rates, work – force levels etc 2Staffingplan– • Also called as the service aggregate

Pdf Sales And Operations Planning S Op Concepts And Models Under Constraints Literature Review

Sales And Operations Planning S Op 101 Smartsheet

Route sheets, also called sequence cards, detail the sequence of events and necessary materials for component production They are more useful for planning than for tracking 1 Routing is done at two different levels At the aggregate planning level, the route card or the process planning layout is used, while at the machine loading level the route sheet used;Aggregate Plan a plan that includes forecast levels for families of products of finishes goods, inventory, shortages, and changes in the workforce Aggregate planning an approach to determine the quantity and timing of production for the intermediate future Disaggregation the process of breaking up aggregate plan into greater detail Master production schedule aS&OP is also called an aggregate plan D S&OP is also called an aggregate plan Capacity decisions are most critical to

Aggregate Planning And S Op Sales And Operations Planning 533 The Nature Of Aggregate Planning 534 Aggregate Pdf Document

Pdf Aggregate Planning For Probabilistic Demand With Internal And External Storage

· What is aggregate planning and what are the contents of an aggregate plan? · Aggregate planning is a marketing activity that does an aggregate plan for the production process, in advance of 6 to 18 months, to give an idea to management as to what quantity of materials and other resources are to be procured and when, so that the total cost of operations of the organization is kept to the minimum over that period The quantity of · In traditional production planning literature, this step is also called "aggregate production planning" The plans are made for groups of similar products, called families, therefore said to be aggregated The costs considered in production planning are the costs of carrying inventory and changing workforce level, as well as the cost of overtime As with the Toyota

What Is Sales And Operations Planning S Op Plex Demandcaster

Sales And Operations Planning S Op Is All About Balancing Supply And Demand Implement Consulting Group

Aggregate planning meaning a method of planning the production of the right amount of a product, at the right time, at the Learn moreAggregate Planning Covers aggregate planning and includes topics such as, aggregate planning inputs and outputs demand and capacity options master schedule and scheduling prHere is the part 2 of my video series which explains aggregate plan, focused on how to find Plan 1 Part 3 will come out real soon To know and get updates o

Sales And Operations Planning Myths Part 3 Supply Chain 24 7

Which Of The Following Is Not An Input To Sop A Capacity Decisions B Supply Course Hero

· INTRODUCTION This unit deals with the concept of 'Aggregate Planning', which is an operational activity which does an aggregate plan for the production process, in advance of 3 to 18 months, to give an idea to management as to what quantity of materials and other resources are to be procured and when, so that the total cost of operations of the organisation is kept to theA forecast of demand for a reasonable longterm planning · Aggregate planning is a proven technique that brings an element of foresight and stability into manufacturing It helps the management to achieve the longterm objectives of a company The importance of aggregate planning include Creates a satisfied and happy workforce

Sales And Operations Planning Aggregate Planning Chapter 10

Pdf Ch8 Aggregate Planning

Traditionally, much of aggregate planning is focused within an enterprise andmay not always be seen as a part of supply chain management Contents of aggregate plan These are the steps followed to prepare aggregate plan Step 1 Identify the aggregate plan that matches your company's objectives level, chase, or hybridIt is also called an aggregate plan what is the process of breaking an aggregate plan into greater detail?The intermediaterange of production planning is called Aggregate production planning It is thus called because of the demand for facilities and available capacities are specified in aggregate quantities For example, aggregate quantities of no of mobile vehicles, the aggregate number of soaps, etc Types of Aggregate Production Planning

Aggregate Planning Inventory Mathematical Optimization

Aggregate Planning Strategy Organization Levels System Examples Model Type Company System

S&OP is also called an aggregate plan Which of the following is NOT one of the features that an S&OP process needs to generate a useful aggregate plan?Topics Discussed1 What is Aggregate Planning?Each of these are further

Chapter 10 Sales And Operations Planning Aggregate Planning Ppt Download

Ppt Chapter 16 Aggregate Sales Operations Planning Powerpoint Presentation Id

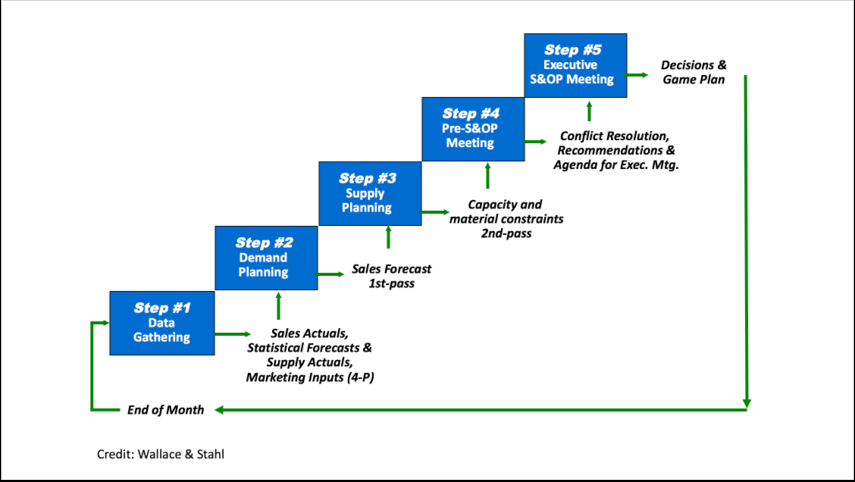

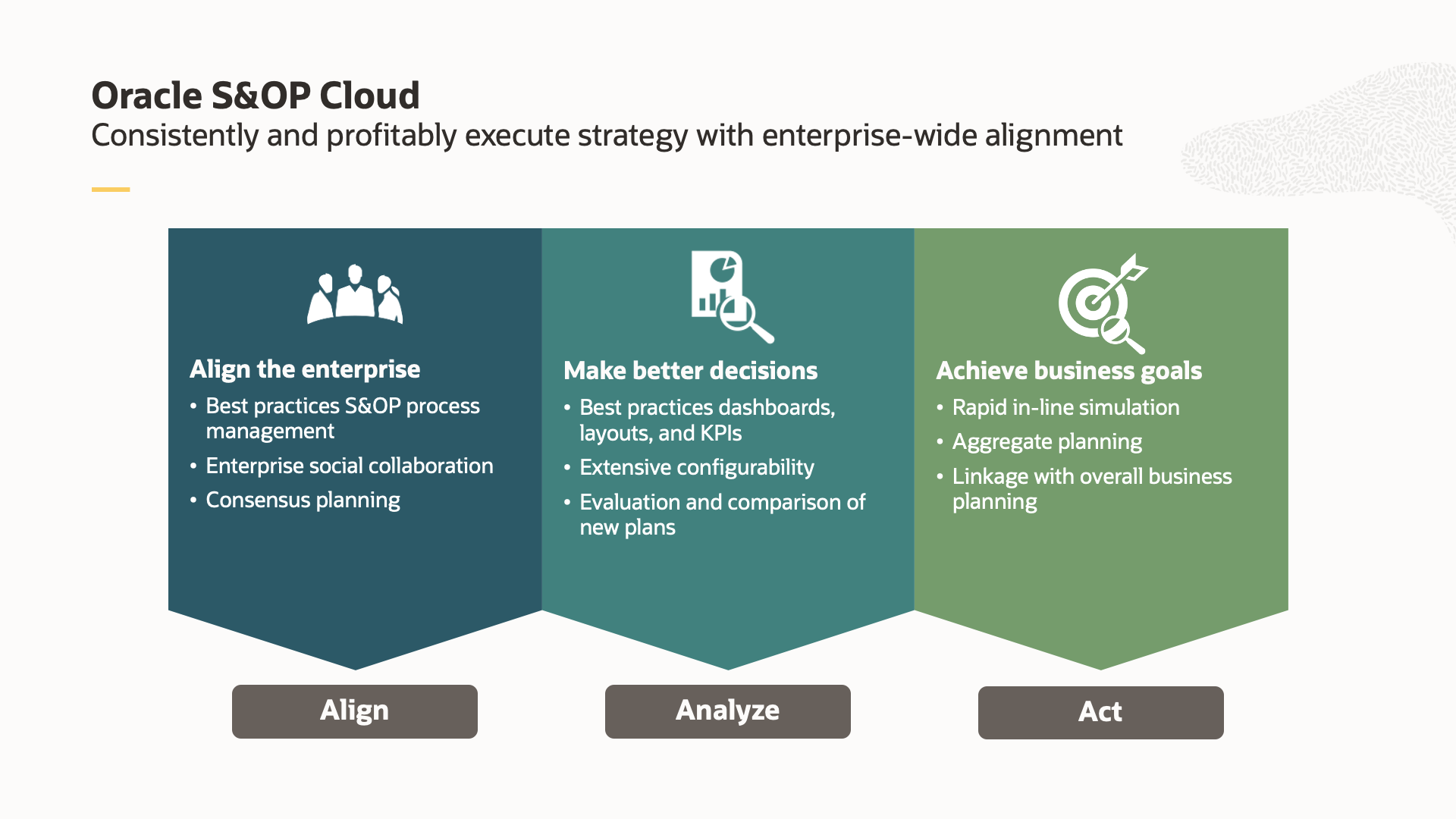

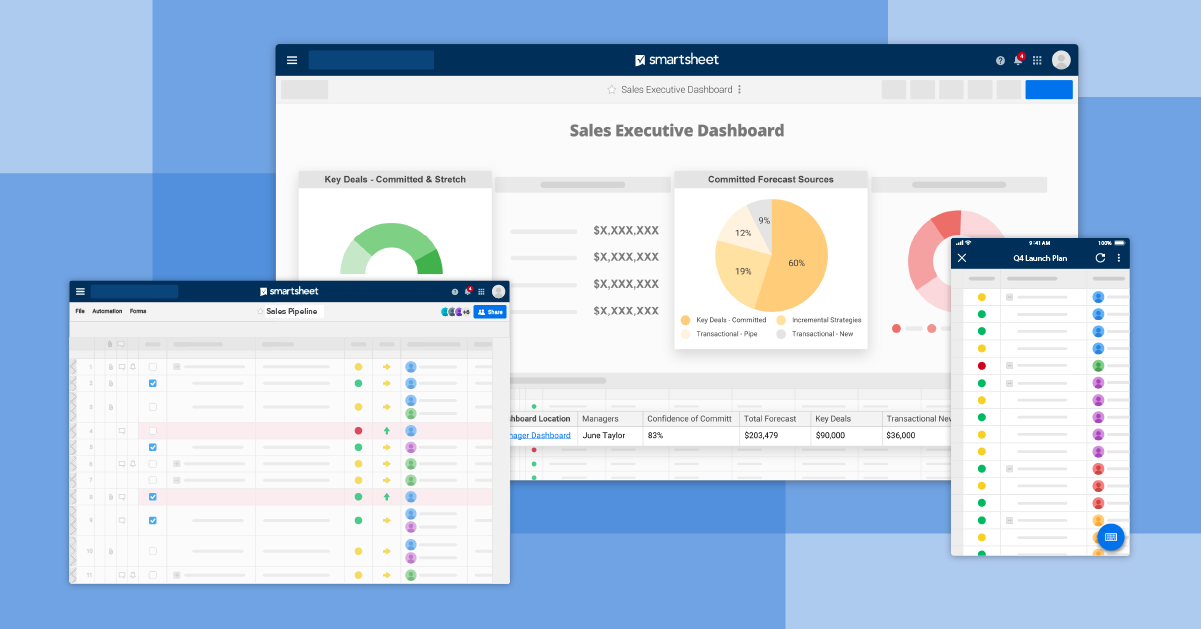

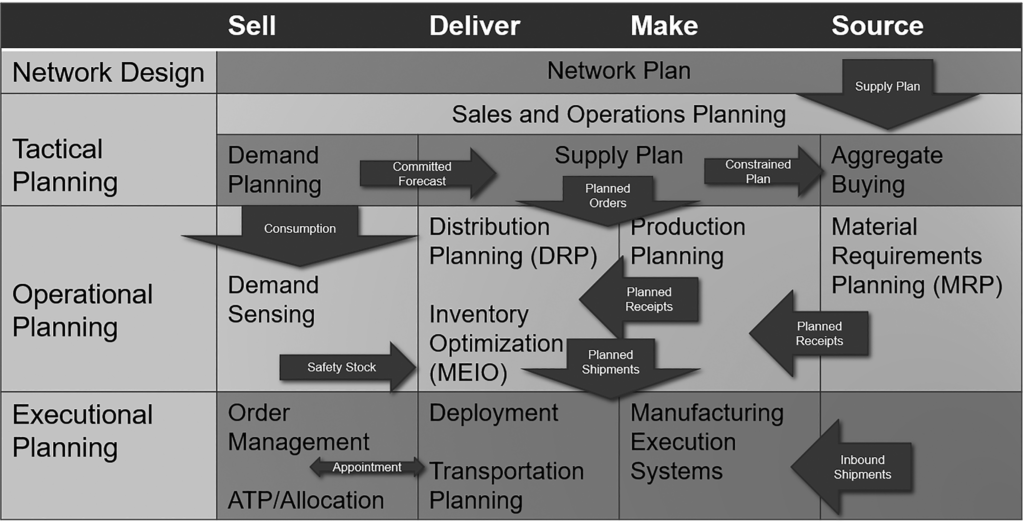

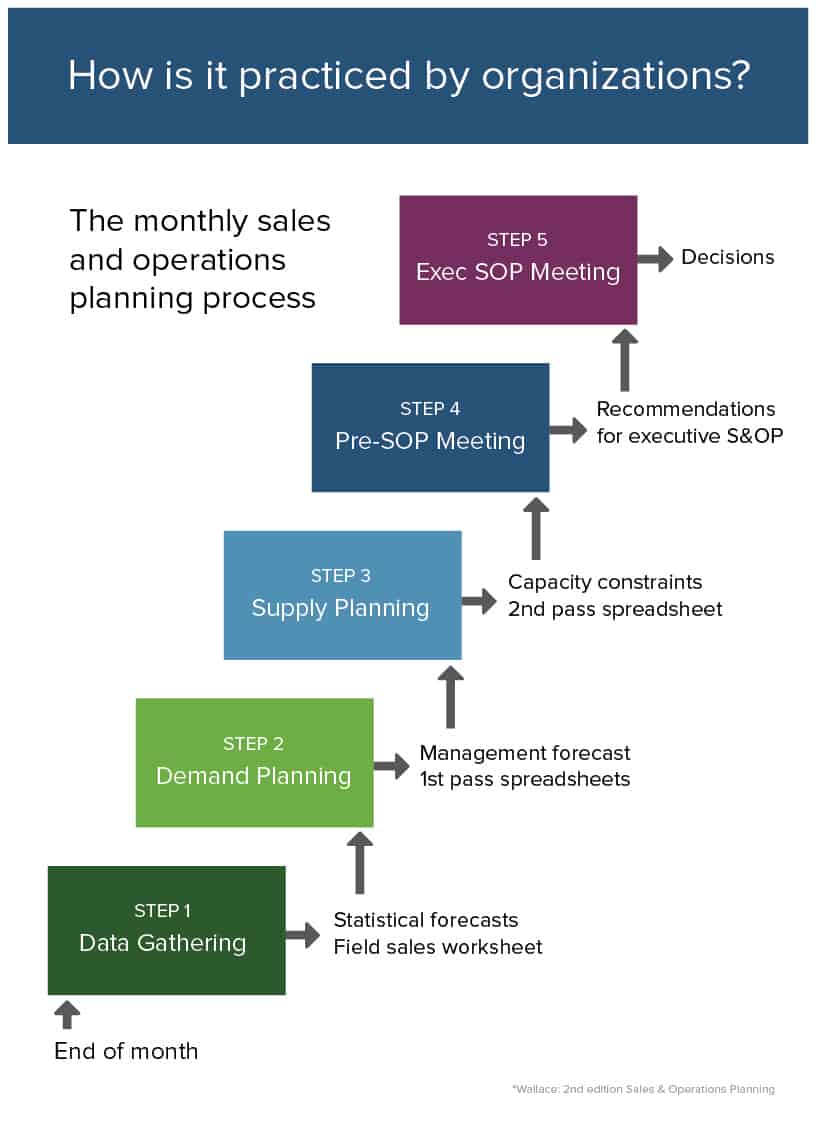

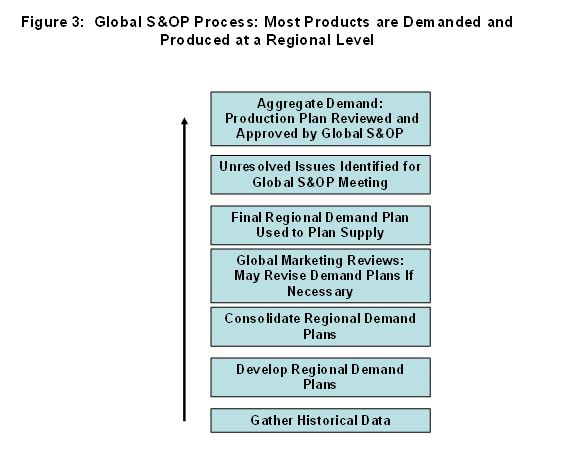

Sales and operations planning (S&OP) A process to develop tactical plans by integrating marketing plans for new and existing products with the management of the supply chain The process brings together all the plans for the business into one integrated set of plans Also called aggregate planning We start by describing how S&OP fits into an organization's planning scheme WeS&OP is also called an aggregate plan Which of the following is NOT one of the features that an S&OP process needs to generate a useful aggregate plan?Aggregate Planning concept, definition and how it works Explained2 Options for situations in which demand

Sales And Operations Planning Aggregate Planning Production Planning Operations Planning How To Meet Effectively And Efficiently Forecasted Requirements Ppt Video Online Download

S Op In The Cloud

Which of the following statements is NOT true about S&OP? · Aggregate planning is the process of developing, analyzing, and maintaining a preliminary, approximate schedule of the overall operations of an organization The aggregate plan generally contains targeted sales forecasts, production levels,With the Aggregate Supply Planning application, you'll know sooner if your demand plan can support the key material and capacity constraints, like long leadtime and/or singlesourced components, outlined in the supply plan If it can't, RapidResponse makes resolving conflicts and eliminating gating issues simple with adaptive collaboration right in the platform Concurrently plan

Oracle Supply Chain Planning Cloud R13 Updates 17b 17d

Case Study The Benefits Of Sales Operations Planning S Op Supply Velocity

Aggregate planning is the process of analyzing, developing and making maintenance of an approximate schedule that is preliminary and is for the overall operations of an organization usually for the future between 3 to 18 monthsQuad 2 what is the primary aggregate planning vehicle in servicePlanning EXERCISE #5 Complete two (2) strategies in aggregate planning as shown in the following tables based on given information 1Demand Nth Regular Production Over Time SK inventory BKO workers 11 Feb Mar Apr May June July Aug Sept Oct Nov Dec Total Co View Answer

Climbing The Sales Operations Maturity Ladder Stage 3 Consumer Goods Technology

Pdf Aggregate Planning Radhika Mittal Academia Edu

· We plan out these and other aspects of business during a process called aggregate planning Aggregate planning is the process of planning thatA S&OP is also called and aggregate plan b S&OP is typically done by crossfunctional teams that align competing constraints c S&OP is used to determine which plans are feasible in the coming months and which are not dWhen the resources appear to be substantially at odds with market expectations, S&OP provides advanced warning to top management · Aggregate planning compiles the information on what a business needs to operate, from sales forecasts to production and inventory, to customer service, and then determines whether there are

S Op Process

Aggregate Planning And S Op 13 Pdf Free Download

Aggregate planning usually includes the development, analysis, and maintenance of plans for total sales, total production, targeted inventory, and targeted customer backlog for families of products The production plan is the result of the aggregate planning process Two approaches to aggregate planning exist—production planning and sales and operations planning · Creating Demands Proactive aggregate planning also gives a way to create additional demand For example, movie theaters having a complementary game store The games in these theaters attract customers while they wait for a movie and in turn, generate more revenue to the owner Mixed Aggregate Planning Strategies Mixed aggregate planning strategies use theFuture (generally 6 18 months);

Sales And Operations Planning S Op 101 Smartsheet

Sales And Operations Planning Adding Supplier Collaboration For Better Results Globaltranz Enterprises Llc

Sales and operations planning assists the organisations to balance the demand and supply This process is also called aggregate planning This planning involves functioning of all the activities of the organisation like sales, manufacturing, operations, finance etc The marketing team develops a sales plan for the coming 3 to 18 monthsAggregate PlanningObjectives of Aggregate PlanningQuantitative Techniques For Aggregate PlanningAggregate plan such as the linear decision rule, heuristic and simulation method, mathematical techniques, and linear programming (Pan and Kleiner, 1995) In our case, we will be using the linear programming method which forecasts demand, hiring, firing and other costs Although linear programming seems to be one of the best methods for solving an aggregate plan, it is based on

Summary Aggregate Planning Aggregate Planning The Planning Process We All Know That Demand Forecasting Can Address And Decisions Manages Translate These Studocu

Demand Sensing Ddmrp Vs Demand Planning Forecasting Blog

Called the "planning horizon " Aggregate Production Planning (Sales and Operations Planning (S&OP)) Sales and Operations Planning is • prepared for product families (ie products with similar labor, material or processing requirements); · The aggregate production will also not specify details such as the dates when material ordered against individual customer order will be ready for delivery The aggregate production plan is designed to establish overall production targets and as input for planning availability of other inputs and supporting activities to meet the production targets The aggregate

Lesson 2 Sales And Operations Planning S Op And Aggregate Planning Ppt Download

Implementing A Sales Operations Planning S Op Process Plex Demandcaster

Sales And Operations Planning Aggregate Planning Production Planning

Sales And Operations Planning Overview

Hierarchical Supply Chain Planning S Op To Execution Supply Chain Link Blog Arkieva

Pdf Integrated Aggregate Production Planning And Marketing Promotion Model And Case Study

Solved M Which Of The Following Is The Term Used For Med Chegg Com

What Is S Op How S Op Works Demand Planning Com

/GettyImages-935338396-5ab92ce4ae9ab800378f6fcb.jpg)

Sales And Operations Planning

What Is S Op How S Op Works Demand Planning Com

Chapter 13 Aggregate Planning And S Amp Opaggregate Planning And S Op Operations Management Sustainability And Supply Chain Management Twelfth Edition Book

Aggregate Sales And Operations Planning Youtube

Aggregate Planning Strategy Organization Levels System Examples Model Type Company System

Chapter 11 Aggregate Planning And Master Scheduling Chapter

Forecasting And Aggregate Planning Vskills Tutorial

Production And Material Requirements Planning Springerlink

Why S Op Needs In Memory Computing Toolsgroup

Session17 Ch13 1 Lecture 1 Pptx University Of Windsor Odette School Of Business Operations Management I Chapter 13 Aggregate Planning And Sales And Course Hero

Proposal Of A Model For Sales And Operations Planning S Amp Op Maturity Evaluation

Proposal For A Reference Model For Sales Operations Planning And Aggregate Planning By Ijaers Journal Issuu

Aggregate Planning An Overview Sciencedirect Topics

What Is S Op Or Sales Operation Planning Sales And Operation Planning Definition And Steps

Lesson 2 Sales And Operations Planning S Op And Aggregate Planning Ppt Download

Lesson 2 Sales And Operations Planning S Op And Aggregate Planning Ppt Download

Is S Op Excellence Slip Slidin Away Supply Chain Shaman

Sales Operations

Top 11 Sales And Operations Planning S Op Software In 21 Reviews Features Pricing Comparison Pat Research B2b Reviews Buying Guides Best Practices

Aggregate Planning Definition Importance Strategies Management And Advantages

Chapter 13 Aggregate Planning Ppt Video Online Download

Proposal For A Reference Model For Sales Operations Planning And Aggregate Planning By Ijaers Journal Issuu

Aggregate Planning Inventory Demand

Sales And Operations Planning S Op 101 Smartsheet

Sales And Operations Planning Aggregate Planning Production Planning

Supply Chain Planning Algorithms Serus Corporation

Chapter 13 Aggregate Planning And S Op Youtube

Ch 8 Sales Operations Planning Flashcards Quizlet

Solved You Are The Director Of Supply Chain Planning Over Chegg Com

Pdf Sales And Operations Planning S Op Concepts And Models Under Constraints Literature Review

Chapter 16 S L D O I Pl I Sales And Operations Planning

Sales And Operations Planning Overview

Sales Operations Planning In Supply Chain Management Business Class 21 Video Study Com

Ppt Capacity And Aggregate Planning Powerpoint Presentation Free Download Id

Sales Operations Planning The Science Behind Inventory Planning In The European Food Industry

Sales And Operations Planning Aggregate Planning Ppt Video Online Download

Aggregate Planning An Overview Sciencedirect Topics

What Is S Op How S Op Works Demand Planning Com

What Is S Op How S Op Works Demand Planning Com

1 Aggregate Planning 2 Process Planning Long Range

Aggregate Plan And Master Production Schedule Linkage Springerlink

Solved M Which Of The Following Is The Term Used For Med Chegg Com

Aggregate Planning An Overview Sciencedirect Topics

A Case Method For Sales And Operations Planning A Learning Experience From Germany

Aggregate Planning And S Op

Ppt Capacity And Aggregate Planning Powerpoint Presentation Free Download Id

Aggregate Planning Inventory Demand

Sales Operational Planning S Op Versus Integrated Business Planning Ibp Supply Chain Link Blog Arkieva

Aggregate Planning Strategy Organization Levels System Examples Model Type Company System

Introduction To Aggregate Planning And Strategies Springerlink

Introduction To Aggregate Planning And The 3 Plans Level And Chase Strategy Included Youtube

How Does A Supply Chain Planning System Aggregate And Disaggregate Data Supply Chain Link Blog Arkieva

Mktg 372 Chapter 13 Aggregate Planning Flashcards Quizlet

Operations And Supply Chain Management Aims Uk

0 件のコメント:

コメントを投稿